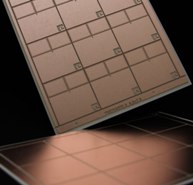

DCB / DBC Substrate

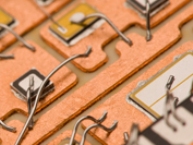

DCB-Substrates (Direct Copper Bond) - or DBC-Substrates (Direct Bond Copper) of AL2O3 (Alumina) or AIN (Aluminium Nitrid) is a widely acceptable and a timeproven technology for power electronic products. The high thermal conducctivity, high current capacity and heat dissation of the high-purity copper on ceramic make the direct bond copper substrate (DBC) essential for electronoc power applications.

We have a short lead time for samples and high series demands.

Typical applications are power switches like IGBT and MOSFETS mostly use in power electronic, laser-applications, Solar Application and automotiv-applications like HYBRIDE CARS.

Advantage of Direct Bond Ceramic (DCB):

- Very high temperature resistance and thermal cycling reliability

- Outstandig heat conductivity. 24 W/mk Al2O3 und 180 W/mK AIN

- High electrical isolation > 15 KV/mm

- Low CTE (coefficient of thermal expansion) 6,8 ppm - AL2O3 und 4,0 ppm - AIN

- Excellente metallization adhesion. Initial and after thermal cycling

- Good mechanical strenght and stability

- High current handling capacity, depending from copper thickness 0,12mm; 0,2mm; 0,3mm und 0,4mm

Our LVM (low volume manufacturing) DBC program will be available for orders that may not meet the minimum requirements for a normal production run with other manufactures. LVM orders may be limites to select material configuratiions and quantities.

Particularly for development departments, research companies and universities we help to start new appications on dcb-substrates.

Easy To Buy From mean after the receive of your DXF-File from the Top- and Bottom-layer you will receive our quotation quickly.

|

DBC Substrates for power applications you can order with different copper thickness and finish.

|

|

|

Applicationen: |

|

|

DBC Direct Bond Copper Substrates > Alumina with Copper Thickness

|

. |

|

DBC Direct Bond Copper Substrates > Aluminium Nitrid - and Copper Thickness

|

|

|

Line & Spaces Copper Thickness Line Space Pitch

|

|

|

Cu Etching Tolerances

Please do not hesitate to call or send an email in case of questions |

|