Metal Matrix Composites

Metal-Diamond composites such as aluminium-diamond, copper-diamond or silver-diamond are composite materials which allow to combine a high thermal conductivity (range from 300 to 650 W/mK) with a tailored (significantly reduced) coefficient of thermal expansion (between 6 to 12 ppm/K). These materials are of interest for applications as heat sinks, heat spreaders, heat slugs or base plates to provide a reliable and sufficient cooling.

We offers Metal-Diamond composites with properties tailored in a certain range. Aluminium-Diamond, Copper-Diamond and Silver-Diamond MMCs.

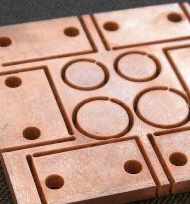

Metal-Diamond plates can be produced in various size between 10mm x 10mm to 150mm x 150mm with thickness typically ranging from 2 – 20 mm. Due to the use of sandwich technology Hot Pressing technology is able to provide plates with a high surface quality.

By using hot pressing technology to prepare these type of materials, it is possible to realize sandwich structures or even parts with a certain complexity. Examples for applications of this type of materials are given in several areas of micro, power- or optoelectronic devices such as: Heat spreaders or lids for CPUs in high performance computing or server applications; Cooling plates for LED or laser diodes; Base plate for high power module (IGBT)

DiaCool - Metal-Diamond Composites is a high Performance Materials for ElectronicCooling

|

Indruduction:

|

|

| Typical Applications: Metal - Diamond Composites combine a high thermal conductivity with a low Coefficient of Thermal Expansion (CTE). Such materials are of interest for applications in electronic industry as:

|

|

|

Properties of Metal - Diamond Composites:

|

|

| Range of properties | Aluminium Diamond | Copper Diamond | Silver Diamound |

| Thermal Conductivity (W/mK) | 400 - 580 | 330 - 620 | 400 - 550 |

| Coefficient of Thermal Expansion (CTE) | 9-14 | 7,2 - 12 | 8 - 12 |

| Density (g/cm³) | 2.8 - 3.0 | 5.5 - 6.5 | 6.0 - 7.0 |