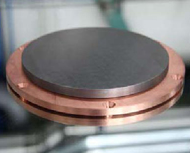

Backing Plate & Bonding Plates

Backing plate and bonding service become important for evaluating a capable sputtering target supplier and is helpful for the customer to get the finished target that can directly used for coating.

We has been dedicated to machining standard backing plate and working together with a special bonding company for providing bonding service.

Backsde Metallization

We sputter deposits backside metallization layers like Ag, Ni, Al on the target before bonding. This metallization accomplishes the characteristics:

- Electriccal and termal contact

- Enhancement of adhesion to the target

- Prevent reaction and diffusion between the target and the solder layer or backing plate

Bonding & Assurance

To improve thermal conductivity under high power inputs, our supplier offers target bonding on backing plates using either Aluminium, Indium and silver based metallic alloy. Durable target bonding requires a varity of pre and post bond functions to assure adhesion. Our quality bonding techniques and process are characterized as following:

- To eliminate cavities an the edges of a solder bond that may entrap air and form a virtual cacum leak in your sputtering system

- To ensure the thermal integrity of the surface between the system´s cooling assembly and the surface of the target

- Zone controlled hot plates for precise contraol of thermal expansion and solderability

- C-Scan imaging system is used to detect material flaws, interrigate bonds and accurately measure thickness

- X-ray radiographic inspection to verify bond integrty