How to get an Hybrid Circuit

Development

Depending on the layout, material, substrate thickness, metallization thickness, etc., special solutions can be offered. We would be happy to help you develop your thick-film substrate.

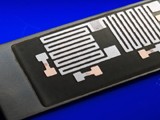

The possible uses for our hybrid circuits, which are based on ceramic substrates (aluminum oxide Al2O3) AlN (Aluminum Nidrid) and stainless steel substrates, have continuously expanded due to their enormous reliability.

We have a comprehensive service portfolio with different manufacturing depths ready for you. From the technology development of your thick-film hybrid circuit to the production of complex hybrid modules, assemblies and OEM products.

- Technology and development advice

- Editing the positions of conductor tracks and the layout

- Development of circuit and programming of algorithms for processors of steering angles of commercial vehicles

- Development of the circuit and software for electronic detonators for mining and tunneling

- Development of power electronics modules such as heating controls

|

|

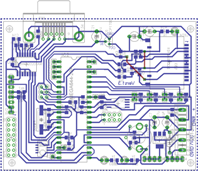

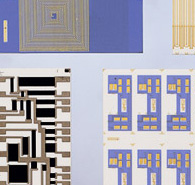

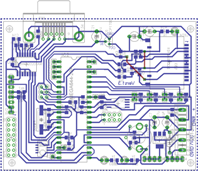

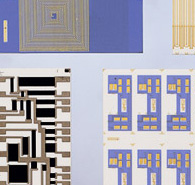

Thick Film Technology

- resistance layers

- resistors

- Capacitors and inducers are printed on AL2O3 and ALN and stainless steel substrates for special applications

- Standard sizes 4 "x6" // 101.6mm x 152.4mm

- Standard thicknesses AL2O3: 0.635mm and 1.0mm

- Other thicknesses: 0.25mm; 0.38 mm; 0.5mm, 0.76mm, 1.27mm

|

|

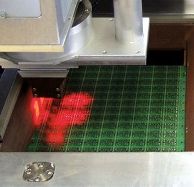

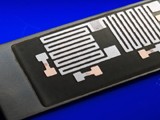

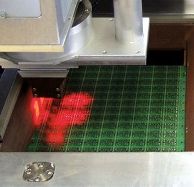

Screen Printing

- screen printing

- Class 10,000 clean room

- Substrates made of AL2O3, ALN and stainless steel are printed

- Typical sizes 4 "x 6", special sizes on request

- Special dimensions on demand

- Multilayer up to 9 resistance layers

- Two-sided printing

- Metallized vias and holes

- Conductor tracks and metallizations: Gold, Silver and Blends

Ag (silver 2 ... 3 mΩ), AgPd (silver palladium 15 ... 50 mΩ),

Pt (platinum 60 ... 100 mΩ), Au (gold 2 ... 7 mΩ),

PtPd (platinum palladium 30 ... 100 mΩ)

|

|

|

Resistance rim

- Das wird im Reinraum Klasse 100.000 durchgeführt

- Widerstandswerte von 0,1 Ω bis 5 GΩ

- TCR (Temperatur Coefficient of Resistance) - 50ppm/°C

*1 ppm = 0,00001%

- Widerstandtrimmung auf der Oberseite

Quality

- ISO/TS 16949 zertifiziert

- Qualitätshandbuch basierend auf der Mil-STD-883 Norm

- Standard Verfahren

- Spezielle Verfahren nach Kunden Anforderungen

- Los Rückverfolgung

- FMEA

|

|