Sputter Targets and Coating Material for your CVD Coating System

We are an solution provider for Sputter Targets, MMC (Metal Matrix Composits) and CMC (Ceramix Matric Composits) parts. Also we sip you powder, granule and small material pices for your CVD System.

Our service is the shipment from small demands like lot size ONE to high valum yearly demands.

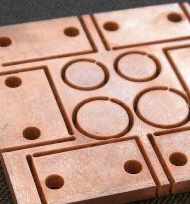

With our HOT Pressing Systems we can develop and ship Metal-Diamond composites such as aluminium-diamond, copper-diamond or silver-diamond composites. The thermal conductivity is tailored on your demand.

Range from 300 to 650 W/mK and a coefficient of thermal expansion between 6 to 12 ppm/K.

These materials are used for applications as heat sinks, heat spreaders, heat slugs or base plates to provide a reliable and sufficient cooling.

|

Metal Matrix Comosites ( MMC) and Metal-Diamond Composites

- The combination of a metallic matrix (e.g. Cu, Ag or Al) with a high termal conductivity in combination with a reinforcement such as diamond with a low Coefficient of Thermal Expansion (CTE) resultes in a material with tailorable thermal properties.

- The theraml conductivity can be varied between 300 t0 650 W/mk

( Kupfer (400 W/mk), Silber ( 430 W/mk) ) und Aluminium 240 W/mk)

- The coefficient of thermal expansion can be varied between 8 ppm/K

to14 ppm/k

Typical Applications:

- Heat Sink of Heat Spreaders in CPUs

- Base plates in Power Electronics (e.g. IGBT base plates)

- Heat Spreders for LED and HB-LEDs

- Heat Sink for RF packages

- Heat Sink for microelectronic packages

- Thermal management of high thermal loaded electronic components

|

|

|

Sputter Targets and Sputter on Demand

- We offer the customized fabrication of targets for sputtering, arc deposition and other thin film deposition techniques with special compositions.

- Batch size ONE is the start for us. We deliver with very short lead time.

|

|

|

Advanced Ceramics

- We offer a broad variety of semifinished ceramic plates made of various materials such as nitrides

- (e.g. Si3N4, AlN,..), carbides (WC, SiC,..) or complex borides (TiB2, AlMgB14,..).

- The size of the semifinished parts can range from 10 mm in diameter to 205 mm.

- Typical geometries: 10 mm x 10 mm up to 200 mm x 200 mm (for some materials up to 250mmx250mm)

|

|

|

Rapir Hot Pressing

- is a pressure assisted sintering technique allowing the consolidation of high performance materials such as special alloys.

- Ceramics as well as metal or ceramic matrix composites up to a temperature of 2.400°C. This is possible in overall cycle times of less than one hour and therefore very economic.

We have 3 differend Rapit Hot Pressung processes

Materials:

WC without binder

W, Mo, Nb, and Ta-Oxide

Ti Carbid, Boride or Nitride

Cr, or Ti Siliczium

ZnS/SiO2

Sulfide like MoS2, WS2

Different metal allyies and ceramic combination

|

|

|

|

|

|